Make New Discoveries

Firstly, we believe that the new-generation, professionally designed and constructed, gyrocopters are inherently safer than fixed wing and helicopter aircraft of similar size. Why? Because a gyrocopter can descend vertically under full control and land in just a few metres of space, without the complexity or cost of a helicopter. So a new-generation gyro always provides more options in case of emergency than a fixed-wing and is less likely to experience a technical failure than a helicopter.

So why is the ARGON the safest gyrocopter?

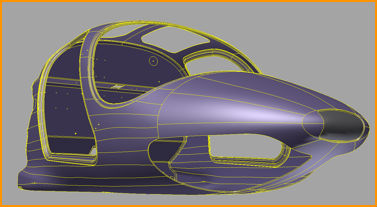

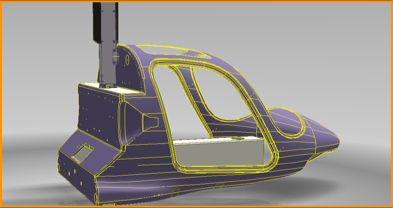

Most gyrocopters are built around a metal chassis, to which everything else is mounted, like cars were until recent years. The ARGON is different. Using the latest carbon fibre technologies, the cabin of the ARGON is an engineering work of art. It is constructed around a light but immensely strong monocoque protective shell, like a formula one car. This shell provides both a crush-proof protective enclosure for the crew and allows all the other components to be directly mounted to it, without the weight of a chassis or additional structural frame.

This provides a massive degree of safety

for the crew in the event of any kind of accident, because the cabin is capable of withstanding loads that are many times the acceleration of gravity.

Monocoque fuselage construction means that forces are transmitted through the fuselage instead of via the rods and tubes of a frame. ARGON is one of the few gyrocopters in the world that uses monocoque construction, and it is now available in carbon-fibre, which offers unparalleled strength and low weight for safety and performance.

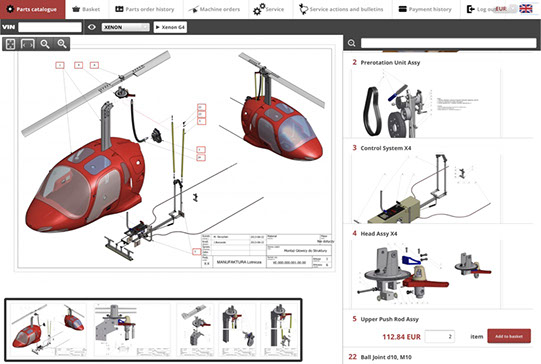

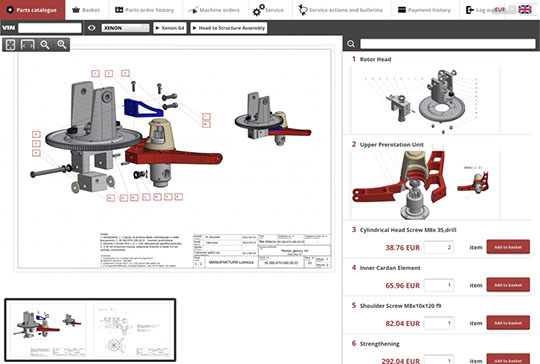

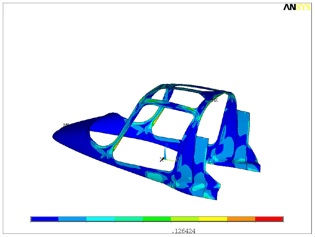

In the design process

sketches and drawings are transferred to Computer Aided Design (CAD) software, which then allows precise rendering from any angle and computational performance testing to check the ergonomics of the machine, and make rapid and cost-effective refinements, before even manufacturing a prototype.

Our cabin is also equipped with controlled crumple zones, just like a modern car. The most important is the nose of the cabin, which in the event of a collision, progressively absorbs the energy to protect the crew. Another important crumple zone is the bulkhead wall separating the cockpit from the engine compartment. It is a structure that is carefully reinforced with composite profiles. The ARGON cabin has also been designed with large pilots in mind, allowing even tall and wide individuals to feel comfortable. As a result, the ARGON offers better safety, cabin volume and comfort than any other gyrocopter in its class.

Ergonomics and ease of use, combined with ultra-modern technical solutions, lie at the core of ARGON. But at the same time, at Manufaktura, we have a very great respect for nature. Over millions of years, dating back to the dinosaurs and before, nature has evolved very effective ways to deliver strength and agility at the least weight and cost. The ARGON borrows from nature through biologically-inspired features such as the reinforcing ‘ribs’ in the cabin and the use of ‘honeycomb’ materials.

Take for example the seat. Made from carbon composite and foam-filled Kevlar, This design is able to save our spine in an accident. The seats can also “crumple”. Similarly, just as a blade of grass or a young, flexible sapling might survive a severe storm, whereas an old and strong tree might fracture and fall, nature has lessons for us about providing flexibility in structures that yield, rather than snap, under load.

But the real test is the moment where theory meets practice, starting with the strength tests that are part of our rigorous certification procedure. Together with the Institute of Aviation at the Technical University of Warsaw, we conducted a comprehensive study of the strength of the cabin and associated components. This not only confirmed the expected strength, but to everyone’s surprise and delight, exceeded predictions.

15 YEARS

OF EXPERIENCE

In conclusion, the ARGON cabin is the result of exploring leading-edge technologies through hundreds of hours invested in analysis, testing, and verification of the concept in practice, over 15 years of research and development. Looking at the finished design you can perhaps now appreciate that virtually nothing was left to chance; every item is the result of many hours invested in the project to achieve maximum safety, comfort, and performance at the most efficient cost.

The mast is a critical part of the structure. During the design process, engineers have to reconcile seemingly contradictory requirements, providing strength without sacrificing flexibility, and firmly supporting the cabin with the lift from the rotors, while allowing the rotor blades to spin freely and to be angled in pitch and roll.